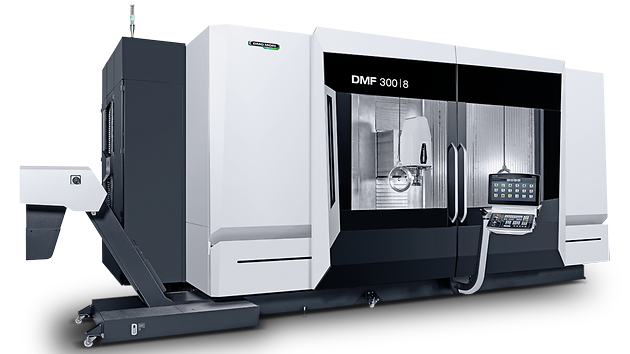

DMG MORI DMF 300|8 Traveling column machine

The DMG MORI DMF 300|8 is a travelling column machine of next generation for 5-axis simultaneous machining

Highlights:

Maximum Flexibility

- Comprehensive modular construction kit enables the right solution for your request

- 4-axes or 5-axes machining with B-axis and integrated NC table

- Mill-Turn Technology for machining of highly complex geometrics on one machine (optional

Constant rigidity enables a high chip volume and a maximum productivity

- New basic construction with constant overhang in the whole working area

- 3 linear guide ways in X-axis and single piece machine bed made of cast iron

- Spindles from 15,000 to 20,000 rpm and up to 200 Nm

High accuracy and best surface quality of the machined workpieces

- Very high thermal longterm accuracy based on comprehensive cooling measures

- Direct drives in Y- and Z-axis

- Dynamic package with linear drive in X-axis (optional)

Maximum productivity for your shopfloor

- Unique tool change ouside of the working area

- Tool magazine with up to 90 pockets and a tool length of up to 400 mm

- Variety of machine tables - perfect for all requirements

- Avoidance of idle times based on the optional partition wall (optional)

- Increase of productivity based on DMG MORI Technology Cycles, e.g. angularTOOL

Technical specifications:

Max. X-Axis

Max. Y-Axis

Max. Z-Axis

Max. workpiece length

Max. workpiece width

Max. workpiece diameter

Max. workpiece height

Max. workpiece weight

Max. Y-Axis

Max. Z-Axis

Max. workpiece length

Max. workpiece width

Max. workpiece diameter

Max. workpiece height

Max. workpiece weight

3.000 mm

800 mm

850 mm

3.300 mm

850 mm

1.050 mm

900 mm

3.00 kg

800 mm

850 mm

3.300 mm

850 mm

1.050 mm

900 mm

3.00 kg